“`html

As the mercury drops across the New York Tri-State area, commercial property managers face a recurring, high-stakes adversary: the deep freeze. While a residential pipe burst is a headache, a commercial freeze-up is a catastrophic event. In a sprawling warehouse, high-rise office building, or retail complex, a single ruptured fire sprinkler line can discharge hundreds of gallons of water per minute, leading to massive structural damage, inventory loss, and prolonged business interruption.

Effective commercial pipe freeze prevention is not merely about turning up the thermostat. It is a rigorous, technical process that involves understanding fluid dynamics, building envelope integrity, and the specific mechanics of fire suppression systems. When water freezes, it expands by approximately 9%. Within the confines of a steel or copper pipe, this expansion exerts upwards of 2,000 psi of pressure. This force is more than enough to shatter fittings and rupture pipe walls. The true disaster, however, often remains hidden until the thaw, when the ice plug melts and creates a path for pressurized water to flood the facility.

For building superintendents and facility directors, the goal is proactive mitigation. This guide outlines the essential strategies to harden your facility against winter’s most expensive threat.

The Cost of a Freeze-Up

The financial implications of a commercial freeze-up extend far beyond the plumber’s invoice. For a commercial property restoration specialist, we categorize these costs into three tiers: immediate physical damage, operational downtime, and long-term liability.

Physical damage includes the obvious—saturated drywall, ruined flooring, and destroyed electronics. However, in a commercial setting, the secondary damage is often more severe. Water migrating through floor slabs can damage the ceilings and equipment of tenants on lower floors. In warehouses, specialized racking systems can suffer structural compromise, and sensitive inventory may be rendered unsalable due to moisture or mold growth.

Operational downtime is perhaps the most significant “hidden” cost. If a fire sprinkler system is compromised, the building may be placed under a “Fire Watch,” requiring dedicated personnel to patrol the premises 24/7. In many jurisdictions, a non-functional fire suppression system is grounds for an immediate evacuation order, halting revenue-generating activities. Furthermore, insurance premiums often skyrocket following a large-loss water claim, particularly if the investigation reveals a lack of preventative maintenance according to NFPA standards.

Vulnerable Areas in Commercial Buildings

Identifying “cold spots” is the first step in commercial pipe freeze prevention. Large commercial structures often have microclimates; while the lobby is a comfortable 72°F, a remote mechanical room or a loading dock soffit might be hovering near freezing.

- Entryways and Loading Docks: Constant foot or vehicle traffic allows massive amounts of cold air to enter. If pipes are located near these openings, they are at immediate risk.

- Attics and Crawl Spaces: Often overlooked during routine inspections, these unconditioned spaces house critical supply lines and sprinkler branch piping.

- Mechanical Rooms with Louvers: Many mechanical rooms have air intake louvers for boiler combustion. If these louvers remain open during extreme cold, they can create a localized freezing environment for nearby plumbing.

- Soffits and Overhangs: Decorative architectural features often hide dry-pipe or even wet-pipe extensions that are susceptible to the “wind chill” effect if the insulation is displaced.

Property managers should utilize thermal imaging cameras during the first cold snap of the season to identify thermal bridges—areas where heat is escaping and cold is penetrating the building envelope.

Managing Sprinkler Systems (Wet vs. Dry)

Fire suppression systems are the most frequent victims of winter freeze-ups. Understanding the nuances of your system is vital for compliance with the NFPA 25 Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems.

Wet Pipe Systems

In a wet pipe system, the pipes are constantly filled with pressurized water. These are common in climate-controlled office environments. The primary prevention strategy here is maintaining a minimum ambient temperature. NFPA 25 requires that these areas be maintained at a minimum of 40°F (4.4°C). If a portion of the system passes through an unheated area, it must be protected by insulation or heat tracing.

Dry Pipe Systems

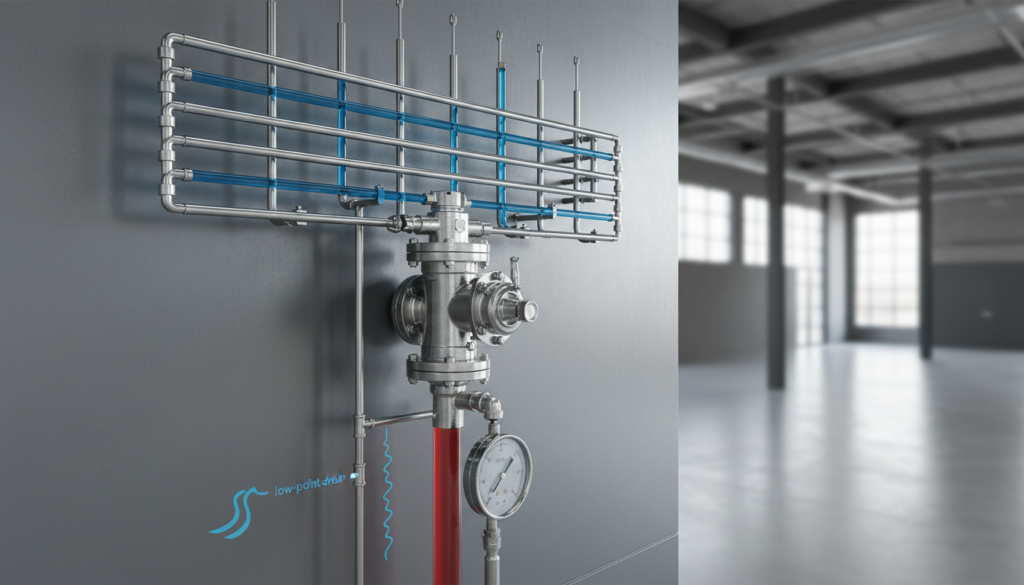

Dry pipe systems are designed for unheated areas like warehouses or parking garages. Instead of water, the pipes are filled with pressurized air or nitrogen. When a head activates, the air escapes, and a “dry pipe valve” opens to let water into the system. However, dry systems are not “set and forget.” Condensation often accumulates in the low points of the piping (drum drips). If this condensate is not drained, it will freeze, cracking the pipe or preventing the system from functioning during a fire.

| System Type | Freeze Risk | Prevention Strategy |

|---|---|---|

| Wet Pipe Sprinkler | High (in unheated areas) | Maintain heat >40°F, Insulate, Thermal monitoring |

| Dry Pipe Sprinkler | Low (if maintained) | Drain condensate (drum drips) regularly, maintain air compressors |

| Supply Lines | Medium | Heat tape, Insulation, Air sealing, Recirculation pumps |

Regular maintenance of the dry pipe valve room is also critical. These rooms must be heated, as the valve itself contains water on the supply side. A failure of the heater in a dry pipe valve room can lead to a massive failure at the core of the system.

Building Envelope Inspections

A building’s “skin” is its first line of defense. For commercial property managers, an annual pre-winter inspection of the building envelope is mandatory. This involves more than just looking for broken windows; it requires a detailed analysis of air infiltration points.

Seal the Gaps: Even a tiny gap around a cable penetration or a settling crack in a masonry wall can allow a “jet” of freezing air to hit a pipe. Use high-quality expander foams and caulk to seal these penetrations. Pay close attention to where the roofline meets the exterior walls, as these areas are prone to air leaks.

Insulation Assessment: Over time, batt insulation can sag or be moved by rodents or previous contractors. Ensure that pipes in exterior walls are insulated behind the pipe (between the pipe and the exterior wall) to allow the pipe to benefit from the building’s interior heat. Simply wrapping a pipe in foam sleeves is often insufficient in the NY Tri-State area if the ambient air temperature stays below freezing for multiple days.

The Chimney Effect: In high-rise commercial buildings, the “stack effect” can pull cold air in through ground-floor openings and push it through vertical shafts. This can cause unexpected freezing in stairwells or elevator shafts where plumbing is present.

Emergency Response Protocols

Despite the best preventative measures, extreme weather events can overwhelm systems. Having a documented emergency response protocol is what separates a manageable incident from a large-loss commercial water damage disaster.

- Know the Shut-offs: Every building superintendent and security officer should know the exact location of the main water shut-off valves and the zone valves for the sprinkler system. These valves should be clearly labeled and easily accessible (not blocked by pallets or equipment).

- Contact Information: Keep a “Emergency Ready” list that includes your fire sprinkler contractor, your plumber, and your restoration partner. In a regional freeze event, these professionals will be in high demand; being a preferred client with a pre-existing relationship is vital.

- The “No-Heat” Drill: If the building loses its primary heating source, have a plan for portable heating units. Ensure these units are used safely to avoid fire hazards, and focus heat toward the most vulnerable plumbing runs.

Upper Restoration specializes in assisting property managers with these scenarios, providing rapid extraction and structural drying to minimize the “time-to-occupancy” after a burst occurs.

Remote Monitoring Solutions

In the age of the Internet of Things (IoT), “walking the floor” isn’t the only way to monitor your facility. Smart building technology has revolutionized commercial pipe freeze prevention.

Low-Temperature Sensors: These wireless sensors can be placed in high-risk areas—such as behind soffits, in mechanical rooms, or near loading docks. They provide real-time alerts to your smartphone if the temperature drops below a set threshold (typically 40°F). This provides a critical buffer of time to intervene before the water reaches the 32°F freezing point.

Flow Sensors: Smart water meters can detect “abnormal flow.” If a pipe bursts in the middle of the night, these systems can automatically shut off the main water valve and alert the property manager, potentially saving tens of thousands of dollars in water damage.

Pressure Monitoring: For dry pipe sprinkler systems, monitoring the air pressure is key. A sudden drop in air pressure may indicate a leak or a failing compressor, which could lead to a “tripped” valve and water entering a freezing environment.

Frequently Asked Questions

Q: At what temperature do commercial pipes freeze?

A: While water freezes at 32°F (0°C), alert thresholds in commercial buildings are usually set at 40°F. This provides a safety buffer to account for sensor calibration and the time it takes for a maintenance team to respond before the water inside the pipes actually reaches a solid state.

Q: Can I use antifreeze in my commercial sprinkler system?

A: Antifreeze loops are used in some systems, but they are strictly regulated by NFPA 25. There are specific requirements regarding the type of antifreeze (usually propylene glycol) and the concentration levels to prevent it from becoming a fire hazard itself. Any antifreeze system must be tested annually by a certified professional.

Conclusion: The Proactive Advantage

Winterizing a commercial property is a complex but essential investment. By focusing on the physics of freezing, adhering to NFPA standards, and leveraging modern monitoring technology, property managers can protect their assets and their tenants from the devastating impact of water damage. Remember, the cost of prevention is a fraction of the cost of restoration.

Don’t wait for the first deep freeze to find the weaknesses in your facility. At Upper Restoration, we specialize in helping commercial clients prepare for the worst. Our expertise in large-loss restoration gives us a unique perspective on how to prevent these disasters before they start.

CTA: Sign up for our Emergency Ready Plan (ERP) before winter hits to ensure your facility is prioritized and protected when the temperature drops.

“`